Retarders

The Portland cements used in well applications are API Class A, C, G, H, and L, and ASTM Type I, Type II, and Type III. These cements, as produced do not have a sufficiently long fluid life (Total Thickening Time) for well applications above 100°F Bottom Hole Circulating Temperature (BHCT). To extend the Total Thickening Time beyond that obtained with neat cement, a chemical agent known as a Retarder is added to cement slurries to increase the Total Thickening Time in order to achieve proper cement slurry placement. In other words, Retarders slow cement hydration to allow for safe cement slurry placement.

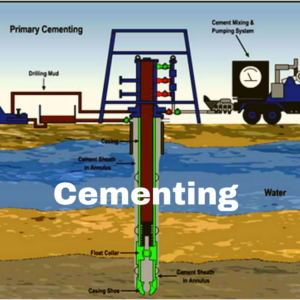

The need for cement retardation increases with depth due to the greater time required to complete the cementing operation, and the effect of increased temperature and pressure on the cement-setting process.

Through our partnership with Domsjö Lignin and The Plaza Group, we are able to provide the DD88 – Sodium Lignosulfonate Retarder and the DD77 – Modified Sodium Lignosulfonate Retarder. Check out the DD88 and DD77 product pages below to learn more about these two Retarders that are ideal for the North American market from a price and performance perspective.